Product introduction

This product undergoes rapid and thorough vulcanization, and will not produce frost spray.The product is milky white and has no effect on white and colored adhesive materials pollution. Using EPDM as the carrierensures the storage stability of the product. This product can completely replace traditional DM/M and di-thioamino groups. Formate salt anti yellowing accelerator has the characteristics of simple operation, nosacrifice of physical properties of the rubber material, and no nitrosamines are produced during the reaction process.Complies with the latestREACH standards.

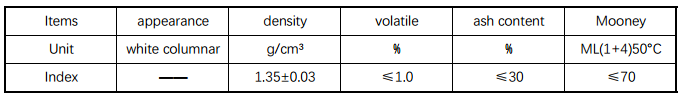

Product index

Usage method

It can be widely used in various rubber compounds such as NR/BR/SBR/NBR/IBR/IIR/EPDM,and can be used as the main accelerator or as a secondary accelerator.

Usage: Use as a general accelerator, add it in the second stage of internal mixing or open mill

Suggested dosage:01.5phr-3.5phr. please increase or decrease as needed

Package specification/ shelf life

25kg/ bag

Twelve months from the date of production. If the storage is expired, it can still be used after re inspection

Attention points

1. This product is flammable, avoid contact with fire

2. Keep away from non-polar oil to prevent its melting and deterioration

3. Store in a well ventilated and dry place